CASE STUDY

Helping to streamline fruit processing operations

Fresh Pak Inc.

Fresh Pak Inc.

Fresh produce. Fresh product. Fresh Pak.” Those are the first words you’ll see when you visit the website at Fresh Pak Inc. Words that have guided them for more than 70 years as they’ve delivered on a promise to bring only the finest products to families all over the Midwest.

What started in 1948 as a spinach processing facility, this family-run business has grown into a supplier of fresh fruits and vegetables for the retail grocery, foodservice and food manufacturing industries.

Vince Riggio CEO, Fresh Pak Inc

“Our primary goal is to provide the freshest and safest product possible to our customers.”

Fresh produce. Fresh product

Fresh produce. Fresh product

Owned and operated by Vince Riggio and his two brothers, Dominic and Phil, Fresh Pak sources produce directly from growers with only the finest reputation in quality and food safety.

A standard that they’ve lived up to and a commitment that you’ll find from the boardroom to the factory floor. A few years ago, Fresh Pak expanded its facility with state-of-the-art equipment that offers them an unmatched capability and efficiency with food safety in mind. But that transition didn’t come easy.

Luca Ascari. ABL

“Vince was skeptical when we told him we’d surpass his performance needs, without any sacrifice in quality. We not only met his previous production level but are exceeding it.”

A new way of thinking

For years, Fresh Pak cut fruit by hand. While labor-intensive, and time-consuming, it gave them a level of quality control that they liked. Allowing them to oversee every step of the process so they could be sure that what left their facility met their standards.

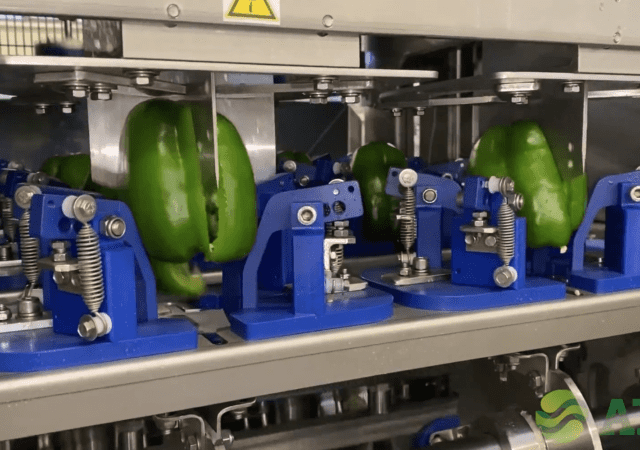

So, when ABL came in and started talking about machine-cut fruits and vegetables, well, naturally there was skepticism. In fact, Vince didn’t think it was possible to do what ABL fruit processing machines could do.

Machines were mostly used for canning, this means there was a greater acceptance for imperfections when it came to the end product. But today, stores are selling more fresh-cut fruit than whole. And while convenience is a huge factor to customers, they don’t want to sacrifice quality.

Vince Riggio CEO, Fresh Pak Inc

“We hoped it would pay for itself in 18 months. It actually happened in six.”

Productivity, quality & consistency

When Vince and Fresh Pak brought in their first ABL machine in 2011, it was more of a test run to see if the machines lived up to the hype, and it didn’t take long to discover that they did.

What the team learned changed their whole approach to the business. It not only streamlined their operation by making the whole process faster and more efficient, but ABL machines also met and lived up to every single quality standard that Fresh Pak had become famous for.

If that wasn’t enough to make a believer out of Vince, the fact that his first machine paid for itself within six months almost certainly did. Ten years later, Fresh Pak has 11 ABL machines at their facility: two washers, four peelers, and two chunkers, with two more peelers and one more chunker on the way.

Why ABL Cavezzo?

Why ABL Cavezzo?

Whether you’re coring, peeling, shelling, drying, or canning every ABL machine is engineered to the highest standards in the industry. That’s the way it’s been for more than 40 years. Designed to deliver what matters most — productivity, quality and consistency. So, companies like Fresh Pak get solutions they can depend on and results they can see.

Contact us